Whether you’re sourcing personal protective equipment (PPE) for a medical facility or supplying respiratory protective equipment (RPE) for workers on a construction site, the reality is that PPE compliance requirements are constantly evolving in response to emerging research and new risks.

Outdated protocols can quickly lead to compliance gaps that expose facilities and employees to specific hazards. With this in mind, it’s essential to regularly review your workplace’s approach to ensure alignment with the latest PPE practices. Here’s how.

Understanding current PPE requirements and standards

Under the model WHS Regulations set out by Safe Work Australia, a person conducting a business or undertaking (PCBU) must implement control measures to protect workers’ health and safety. This includes providing workers with appropriate PPE if it’s deemed necessary to minimise the risk.

Different PPE requirements often apply depending on the industry and the specific risk. For example, workers in a healthcare setting may be required to wear a surgical respirator mask as a form of infection control. Alternatively, workers in industrial settings, such as the mining, manufacturing or construction industries, may be required to wear a P2 respirator mask to protect against inhaling harmful dust or smoke.

Regardless of the type of PPE required by your workplace or industry, it’s essential to ensure that the equipment you source is certified and meets the relevant Australian and international PPE standards. Partnering with a certified supplier, like Detmold Medical, can help to ensure a reliable, consistent supply of high-quality PPE and RPE.

Risk assessment: The foundation of PPE management

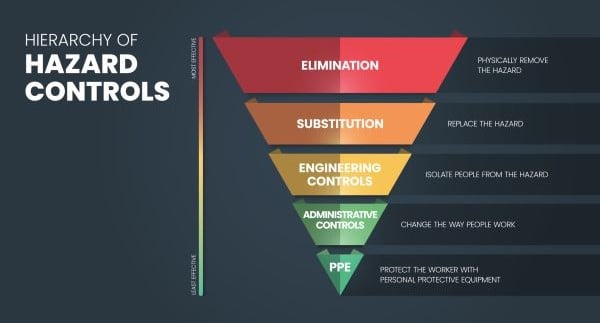

To identify the most suitable form of PPE, you must first conduct a structured risk assessment to identify and evaluate relevant workplace hazards. From here, you would apply the hierarchy of control, implementing specific control measures in order of most to least effective. Under the hierarchy, PPE is considered the least effective form of control measure, so it should only be used as a last line of defence after more effective controls have been implemented.

While it’s important to review your control measures to confirm they’re working as intended, it’s equally important to complete regular risk assessments to ensure you’re maintaining PPE compliance in the workplace.

Fit testing and training: Ensuring PPE works as intended

As a PCBU, you are responsible not only for identifying and providing suitable PPE, but also for ensuring that workers and visitors receive adequate information, training and instructions on the correct use, storage and maintenance of PPE. Poor fit or incorrect use compromises protection and compliance, which is why it’s important to provide fit testing.

Under the Australian/New Zealand Standard AS/NZS 1715:2009, fit testing is mandatory for workers required to wear tight-fitting respirators, whether disposable or reusable. This testing ensures that the respirator forms an effective seal to the wearer’s face, reducing the risk of contaminated air entering through gaps or leaks.

Workers wearing a tight-fitting respirator should also be trained to complete a fit check each time they wear their mask.

Maintenance and replacement: Extending PPE performance

Beyond respirator fit testing and user training, maintenance and storage can significantly influence the effectiveness and longevity of PPE. Failure to maintain PPE undermines compliance, even if the equipment itself is certified. With this in mind, staff should be instructed on:

- Maintenance schedules: Regular inspections are the foundation of effective PPE performance. Assist your employees by developing a schedule that outlines inspection intervals based on usage frequency, environment and manufacturer recommendations.

- Storage protocols: Storage instructions should align with PPE best practices and the manufacturer’s guidance. Improper storage can cause the protective materials to degrade over time, potentially compromising filtration layers in masks and respirators.

- Disposal and replacement guidelines: Every piece of PPE has an expiry date, so while some items may appear “fine” visually, they may no longer perform to standard. Similarly, it’s important to ensure staff are replacing their RPE in line with manufacturer guidance. For example, a surgical mask or P2/N95 respirator can generally be worn for up to four hours before it should be discarded. Alternatively, RPE should be replaced sooner if the mask becomes moist, contaminated, difficult to breathe through or loses its fit or shape.

Closing the compliance gap: Aligning your PPE program with evolving guidelines

Integrating up-to-date PPE guidelines and internal audits is key to ensuring PPE compliance in the workplace. That said, partnering with a reputable PPE supplier can help you streamline your PPE management.

As the Southern Hemisphere’s largest manufacturer of high-quality respirators and face masks, Detmold Medical is trusted by the South Australian Health Department and other leading distributors. With an ongoing commitment to innovation and certified manufacturing standards, Detmold Medical is dedicated to keeping Aussies safe across numerous settings, including the medical, construction, mining and manufacturing industries.

Build a PPE program that meets the latest standards

From healthcare to mining, it’s essential to implement proactive practices that ensure alignment with the latest industry PPE practices. Whether you’re a safety officer, procurement manager or employer, it’s worth auditing your current PPE program to ensure workplace safety and compliance.

For certified RPE solutions that are designed to meet evolving standards, visit Detmold Medical or explore our range of high-quality face masks and respirators.