Respirator masks and surgical masks are only effective to their intended protection level when they are used correctly. An important factor in achieving the maximum protection from a face mask is knowing when to replace your surgical mask or respirator.

How do respirator masks work?

Single-Use P2 and N95 respirator masks are designed to protect the wearer from airborne particles, including airborne viruses, dust, smoke, and other contaminants. Both P2 and N95 respirator performance testing is based on Standards dealing with filtration efficiency, however different classification systems are used across the world. Standards outline the performance requirements, selection and use for respiratory devices by type and style. In Australia and New Zealand P2 masks are tested to AS/NZS 1716:2012 and AS/NZS1715:2009, while N95 masks are tested to the United States National Institute for Occupational Safety and Health (NIOSH) standard.

Both P2 and N95 masks are highly regarded for their filtration efficiency, making them an ideal choice for use in hospitals, healthcare, clinical, or any other challenging environment. These respirator masks are designed to filter out at least 95% of non-oil-based airborne particulates, viruses, and bacteria.

To provide the intended level of filtration efficiency and protection, it is important to make sure the respirator is worn correctly. Respirator masks are designed to form a tight seal around the nose and mouth. This helps to minimise the risk of unfiltered air entering the mask. Under the Australian New Zealand Standard AS/NZS1715:2009 (Selection, use and maintenance of respiratory protective equipment) employees who wear a respirator mask for work are required to undergo fit testing to ensure their respirator mask forms an effective seal on their face.

Beyond taking care that the respirator is fitted properly, it is also important to change a disposable respirator regularly, for effective protection.

Why is it so important to replace your respirator mask regularly?

Disposable P2 and N95 respirator masks are designed for single use only as their effectiveness diminishes over time and is dependent on the environment, including the contaminant, humidity, or activity levels of the wearer.

Replacing your mask regularly is important for several key reasons, including:

- Filtration efficiency degradation: Over time and with use, the filtration efficiency of a disposable mask will degrade due to capture of particles and the loss of electrostatic charge of the filter material. This means that the mask's ability to filter out airborne particles, like smoke, dust and pathogens reduces.

- Moisture accumulation: Breathing through the mask can lead to the accumulation of moisture, particularly if the mask is used for an extended period, during physical activity or in humid environments. Moisture can affect the structural integrity of the mask and reduce its effectiveness in filtering out particles.

- Contamination risk: Respirator masks are designed for single-use or very limited reuse. Reusing a disposable mask may expose the wearer to previously trapped contaminants, increasing the risk of infection.

- Damage and wear: Respirator masks can experience wear and tear, including damage to the straps, nose seal or the filtration material. Damaged masks may not provide a proper seal, compromising their effectiveness.

- Comfort and fit: Over time, the mask fit may become less effective through movement and wear, affecting its ability to form a tight seal around the nose and mouth. An ill-fitting mask is less effective in protecting the wearer from airborne particles.

- Infection prevention: In healthcare settings or situations where infection prevention is crucial, using a fresh, clean mask for each interaction helps minimise the risk of cross-contamination.

- Manufacturer guidelines: Manufacturers typically provide guidelines on the selection, care & maintenance and donning / doffing of their masks. It is important to adhere to specific workplace rules that may be in place, plus local Occupational Health & Safey guidelines or WorkSafe recommendations, to ensure best practice and optimal protection.

When to replace your respirator

When it comes to the question of the best time to replace the face mask you are wearing, there are a few general rules that you should follow:

- Visible damage or wear: If your respirator is visibly damaged, has tears or holes or if the straps don’t provide a snug, comfortable fit anymore, it is time to replace your respirator. Any compromise in the structural integrity of your mask can reduce its effectiveness.

- Moisture buildup: If the respirator becomes wet or moist during use, it may compromise the filtration efficiency. Replace the mask if it becomes visibly damp or wet.

- Difficulty breathing: If breathing through the respirator becomes difficult or uncomfortable, it could be a sign that your mask is clogged with particles or has reached the end of its effective use.

- Extended use: Most disposable respirators are designed for single-use or limited reuse. Extended use beyond the recommended duration may leave you at a higher risk of contamination, especially in hazardous environments.

- Exposure to contamination: If the respirator has been exposed to a high concentration of contaminants or hazardous materials, it should be replaced immediately. Contaminated masks may pose a risk to the wearer and others upon reuse.

Beyond these general guidelines, one of the main factors that can impact the efficiency of your respirator are the specific conditions for use. For example, using your respirator in a dusty environment, like a construction site, will impact your mask differently than if you were working in a healthcare setting.

Here are some examples of different settings and their impact on the need to change a mask:

Smoke

If you experience irritation while wearing the respirator, it could be a sign that the mask is no longer effectively filtering out smoke particles. Keep in mind that using an ineffective or damaged respirator in smoky environments can expose you to harmful particles in the air, so if you feel like your respirator has been compromised in any way, it is always best to swap it for a fresh respirator mask.

If you are exposed to a high concentration of smoke, such as during intense wildfire conditions, you might want to consider replacing the respirator more frequently. High levels of smoke may overload the filtration capacity of the mask.

Dust

P2 respirators can also provide effective protection against hazardous dust, making them an ideal choice of personal protective equipment (PPE) on construction sites and in other dusty environments. If you are exposed to high levels of hazardous dust, it is important to replace your respirator more frequently. High dust levels can overload the filtration capacity of the mask, impacting its ability to effectively filter out harmful dust particles.

Healthcare settings

If you work in a high-risk environment, like a hospital or healthcare setting, it is important to make sure you replace your mask regularly. Workers in healthcare settings, like clinics and hospitals, are often exposed to infectious diseases, so it is important to replace respirator masks between patients.

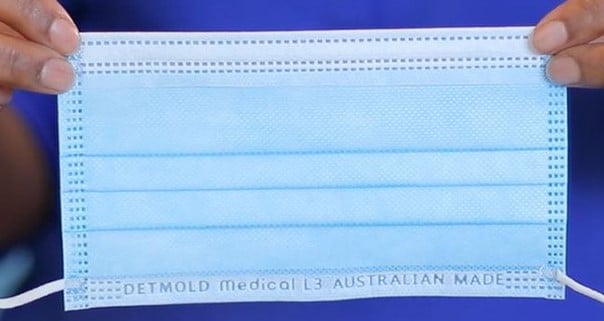

At Detmold Medical, we produce and stock D95 P2 Respirators, N95 Surgical Respirator Masks and Tri-Panel Respirator Masks. Our disposable respirator masks are available in various styles and multiple sizes, so you can be sure to select a suitable face mask and achieve the best fit for you. Explore our range today or have a look at our face mask comparator to find the best mask for your needs.