From healthcare and medical settings to construction, manufacturing and mining, personal protective equipment (PPE) is typically used as a last line of defence to keep workers safe.

But what exactly are the foundations of PPE? In this article, we’ll break down what PPE is, explore the different types of PPE and highlight the key principles that support its proper use. Whether you’re an employer, safety officer or worker, understanding PPE is essential for creating safe and compliant work environments.

What is PPE?

PPE refers to equipment or clothing that protects an individual against potential physical, chemical, biological and environmental hazards. PPE is a common requirement across various industries and workplaces, including medical settings, healthcare, construction and mining, food production, laboratories and manufacturing.

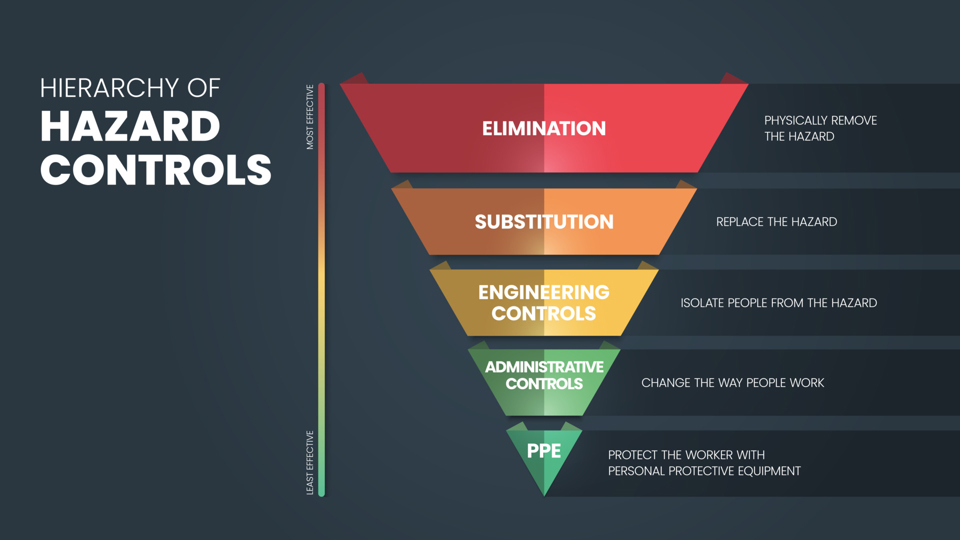

As one of the six categories encompassed by the hierarchy of controls, PPE is considered the least effective method for managing workplace hazards as it relies on individual compliance. With this in mind, it should only be used after other, more effective methods have been implemented. Once workplace hazards have been identified and risks thoroughly assessed, control measures should be implemented in order of most to least effective as follows: elimination, substitution, isolation, engineering controls, administrative controls, and lastly, personal protective equipment (PPE).

In workplace settings, the person conducting a business or undertaking (PCBU) is responsible for determining whether PPE is required and what type of PPE is suitable given the risks. It’s then up to them to provide their workers with appropriate PPE and adequate training. This includes instructions on how to use, clean and store the protective equipment.

The foundations of PPE

There are five core principles that underpin the effective use of PPE. These include:

1. Assessment: Identifying workplace hazards before selecting the appropriate protective equipment. Remember, control measures should be implemented in order of most to least effective, so PPE should only ever be used as a last resort.

2. Appropriateness: Selecting the correct PPE for the specific hazard. For example, using P2 respirator masks in dusty construction settings or safety goggles when there’s a risk of fluid splash.

3. Fit and comfort: Ensuring proper sizing and wearability for optimal protection. For instance, respirator masks must be fit tested under the Australian New Zealand Standard AS/NZS1715:2009 to ensure a correct fit and adequate protection.

4. Training and awareness: Providing thorough instruction and training to ensure workers know how to use, store and maintain PPE equipment.

5. Maintenance and replacement: Inspecting PPE regularly and replacing it when it becomes damaged or compromised. While this differs based on the type of PPE, single-use respiratory protection, like medical and surgical face masks, should be replaced every four hours or when they become damp, soiled or damaged.

Types of PPE

There are numerous different types of PPE that offer protection against various hazards. With this in mind, it’s essential to match the protective equipment to the identified risks. In many cases, workers will wear several different types of PPE while other, more effective control measures are in place.

Common PPE categories include:

- Head protection (helmets and hard hats).

- Eye and face protection (goggles and face shields).

- Hearing protection (earplugs and earmuffs).

- Hand protection (gloves for chemicals, cuts or contamination).

- Body protection (gowns, aprons and protective suits).

- Foot protection (steel-cap boots and anti-slip shoes).

Types of respiratory protective equipment (RPE)

Respiratory protection, including face masks and respirators, is another common form of PPE that’s used to protect workers from airborne contaminants. Different face masks and respirators offer different levels of protection.

Here’s a quick overview of the different types of face masks and respirators to help you understand their uses and when to wear them:

- Medical procedure masks: For clinical or day surgery settings where lower fluid exposure risk.

- Surgical face masks: For environments with risk of blood/fluid splash, including healthcare settings.

- N95 surgical respirator masks: Designed to filter out at least 95% of non-oil based airborne particulates and bacteria, these masks also protect the wearer against blood or fluid splash. Intended for use in hospital and healthcare settings.

- P2 respirator masks: Designed to filter out non-oil based airborne particles in environments where particulate filtration efficiency (PFE) of 95% or greater is required. Recommended for use in hospitals, healthcare and clinical environments that conduct fit checking procedures.

- P2 particulate tri-panel respirator: Designed for use where non-oil based particulate filtration is required, including healthcare, clinical settings and dusty or smoky industrial environments.

- P2 valve respirators: Provide all the features of the P2 particulate tri-panel respirator with the addition of an exhalation valve to allow for enhanced breathability and reduced heat and moisture buildup. Recommended for use in construction and mining settings.

Our Best Sellers

Why PPE alone isn’t enough

While PPE equipment is essential, relying on it as the only line of defence can create a false sense of security. PPE is considered the last resort in the hierarchy of controls because it doesn’t entirely eliminate hazards. It only reduces the risk of exposure when used correctly by the wearer. To build a truly safe workplace, PPE must be part of a broader safety strategy that encompasses a wide range of control measures implemented in line with the hierarchy of control.

As the Southern Hemisphere’s largest manufacturer of high-quality respirators and face masks, Detmold Medical has grown to become the supplier of choice for some of Australia’s largest government healthcare departments, hospital groups and distributors. Explore our range of high-quality face masks and respirators or use our selection guide to find the right RPE for your needs.