A line-up of South Australian women trailblazers have joined in Adelaide to officially open an aptly-named ‘Launchpad’ laboratory, offering face mask and respirator functional effectiveness testing, paper and board repulpability and an Australian-first bag testing facility.

Governor of South Australia Frances Adamson will tour the new R&D laboratory at Brompton, with women leaders of the Detmold Group and Detmold Medical, including Acting Co-CEO Sascha Detmold Cox, R&D Manager Megan Schutte and Chemist Sarah Bagster.

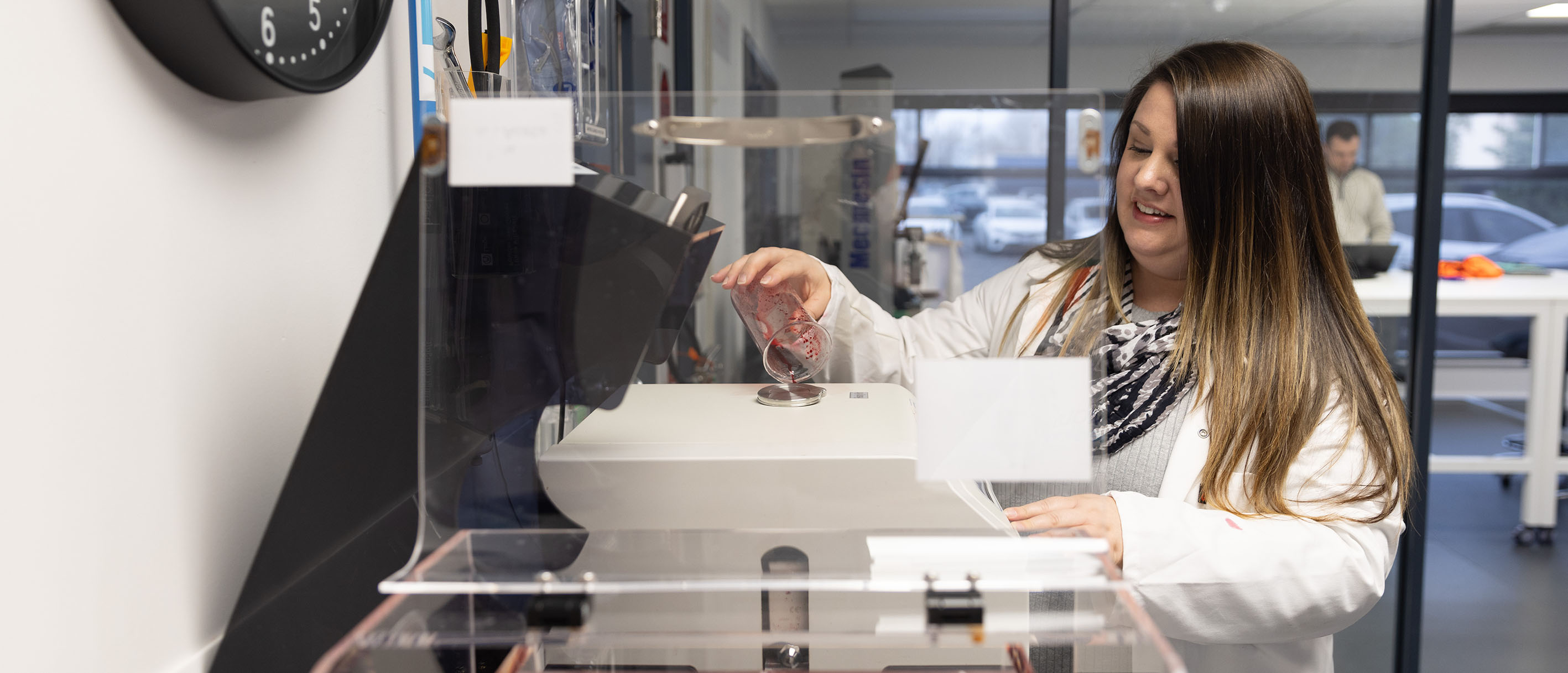

The Detmold Group’s Launchpad laboratory tests medical mask functional effectiveness to AS4381 / AS1716 standards – including filtration testing and blood/fluid penetration testing. This first-class testing facility consistently measures, validates product performance and allows for fast-track approvals, with the capability supporting Detmold Medical’s commitment to providing high quality, easy to wear products.

In 2020, the Detmold Group answered a call from state and federal governments to build local medical mask manufacturing capability in South Australia. In just 18 weeks, Detmold Medical commenced production of surgical masks to protect medical and front-line workers during the COVID-19 pandemic and continues to provide a much-needed quality, supply line.

The Launchpad Laboratory is elevating product capability testing to new standards in Australia and globally, and forms part of the wider Launchpad facility that focusses on innovation, new product development and developing more sustainable products for local and international markets.

Ms Detmold Cox said the $500,000 hub was the first and only dedicated bag-testing facility in Australia and one of only a few laboratories able to test coated paper/board packaging for repulpability – the ability to pulp materials for recycling. The repulpability testing capabilities has been developed in partnership with the Australian Packaging Covenant Organisation (APCO).

“Innovation is essential in our industry, as consumers demand higher quality packaging and medical supplies which are sustainable and effective,” Ms Detmold Cox said.

“Through Launchpad we are now able to offer higher, Australian specific testing standards for businesses and government contractors in the medical, packaging, food and beverage and quick service industries.”

Ms Detmold Cox said the lab had created bespoke testing equipment which replicated the usage of customer products in real world situations. It was also climate controlled for humidity and moisture to replicate oven and refrigeration conditions.

She said the Detmold Group would use the Launchpad laboratory official opening to celebrate women in business and STEM (Science, technology, engineering, and maths) and celebrate South Australia as the national centre of innovation.

“The Detmold Group is investing in South Australia as this is the ideal place for us to reach national and international markets,” Ms Detmold Cox said. “We’ve also invested in our staff, including encouraging women to follow careers in STEM and we appreciate their input and the incredible intellectual rigour that they bring to Detmold, Detmold Medical and our group of companies.”