October 26, 2021

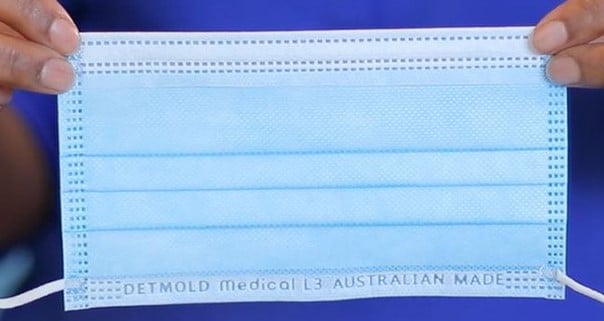

Detmold Medical provides quality assurance of our PPE, thanks to an in-house lab

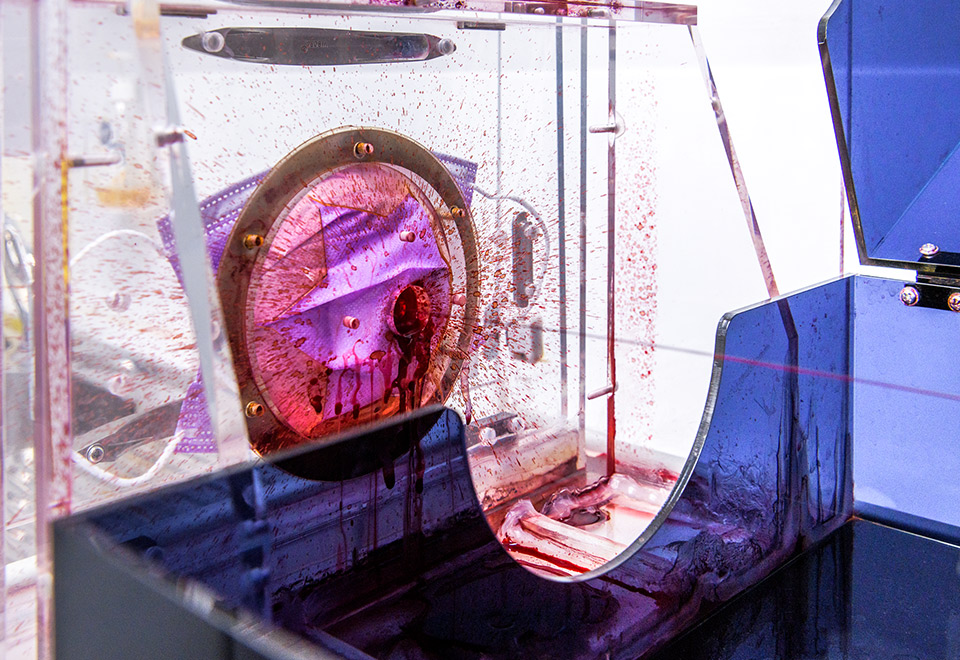

The lab facilitates daily testing of face masks and material to enable continued development of Detmold Medical's extensive PPE range. Regular testing not only validates face mask performance, but also fast-tracks approvals of new and alternative materials.

Our crucial role in establishing PPE testing in Australia

Detmold Medical was founded at a time when Australia did not have PPE testing capability on-shore.

Previously, face masks required to meet Australian Standards were sent overseas for testing. COVID-19 created difficulty in accessing international environments and so collaborative efforts saw Australia develop its own mask testing facilities.

Crucially, as this capability was building, Detmold Medical supplied face mask samples and shared results from our PPE tested overseas with local laboratories as they were upskilling, in order to help validate their procedures.

Through collaboration with Australian organisations such as Flinders University, VicLabs and the CSIRO, Detmold Medical built trusted relationships to facilitate localised testing of PPE.

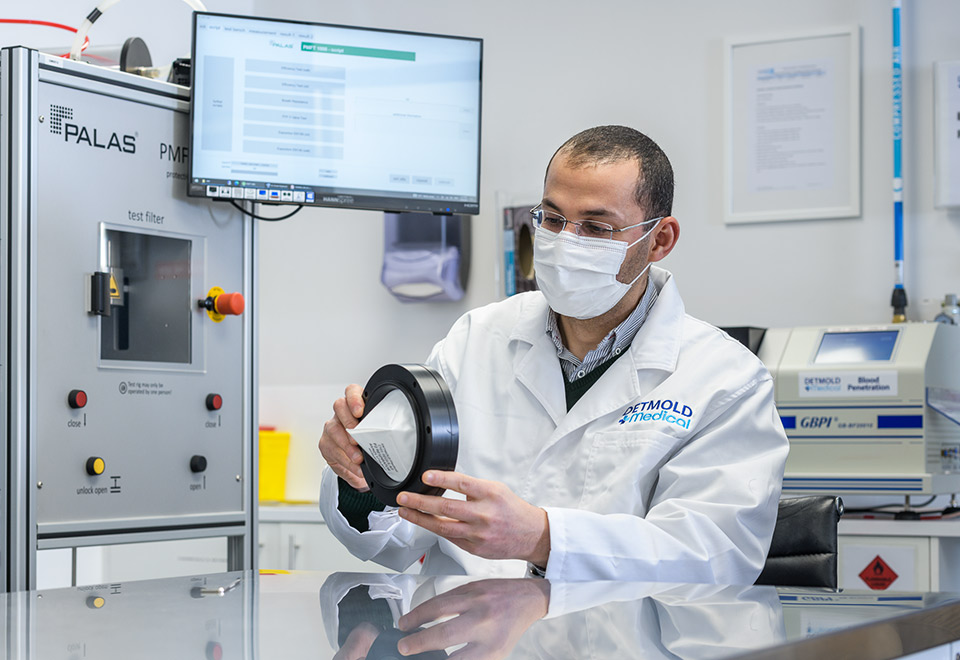

Ahmed Bilasy and Duncan Gunn in the Detmold Medical Lab

Ahmed Bilasy studies a face mask in the lab

Now, Detmold Medical has developed our own testing facilities to validate and enhance the quality of our masks.

The lab allows for constant monitoring of performance, and its proximity to the manufacturing facility ensures issues are quickly identified and resolved.

The onsite testing also fast-tracks approvals of new materials or designs ahead of external validation and testing by accredited laboratories.

Proudly manufacturing in South Australia, we believe making high calibre products for healthcare professionals is immensely important.

Learn about how our manufacturing environment has been created with quality in mind.

Or, back to Latest News.